Advanced equipment

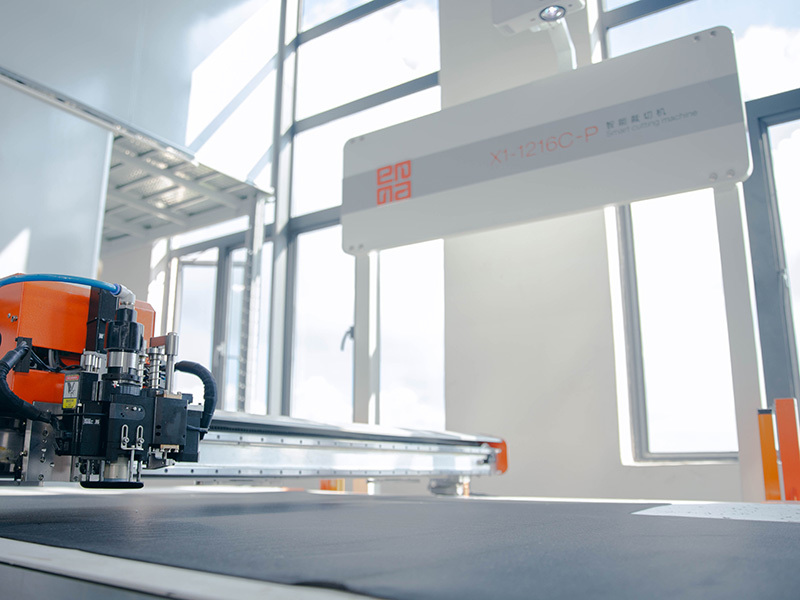

Cutting equipment

The cutting department is equipped with advanced CNC intelligent leather typesetting machine and intelligent double-head cutting machine. The typesetting machine uses full-automatic leather typesetting technology, which can arrange defective leather defects in sewing/folding positions, define component typesetting area/grade/direction, define color matching/pattern typesetting, save 90% of the time compared with manual typesetting, and improve leather utilization rate by 1% ~ 6% compared with manual typesetting. With the typesetting machine, the synchronous use of the intelligent double-head cutting machine further saves the company's labor cost and die cost, and also ensures the cutting accuracy and production efficiency. The intelligent cutting machine supports a variety of cutting methods, such as straight line cutting, curve cutting, arbitrary angle cutting, etc., to meet different production needs. By adjusting the cutting parameters, the intelligent cutting machine can adapt to different materials and cutting requirements.

Edge painting equipment

Edge painting department uses the porduction mode of machine drying in all directions, replacing the original traditional natural drying mode and greatly speeding up the production progress of edge painting. The equipment includes large rotary automatic dryer, vertical rotary automatic dryer and desktop automatic dryer. At the same time, the application of vertical double sided edge painting equipment and desktop double-sided edge painting equipment greatly improves the production efficiency for employees.

Automatic assembly line

In order to vigorously promote lean production, the production workshop is equipped with advanced automatic assembly lines. The use of automatic assembly lines makes it necessary for production management to solve material problems, mold problems, technical problems and quality problems in advance before going online, which greatly reduces the occurrence of production stoppage, and also greatly reduces the chances of waiting for materials and production costs.

Ultrasonic edge pressing machine

The company has an automated ultrasonic edge pressing machine, that makes some semi-finished products that need to be completed in multiple processes completed by single step through the edge pressing machine, which greatly reduces the production cost of the product.