Production advantages

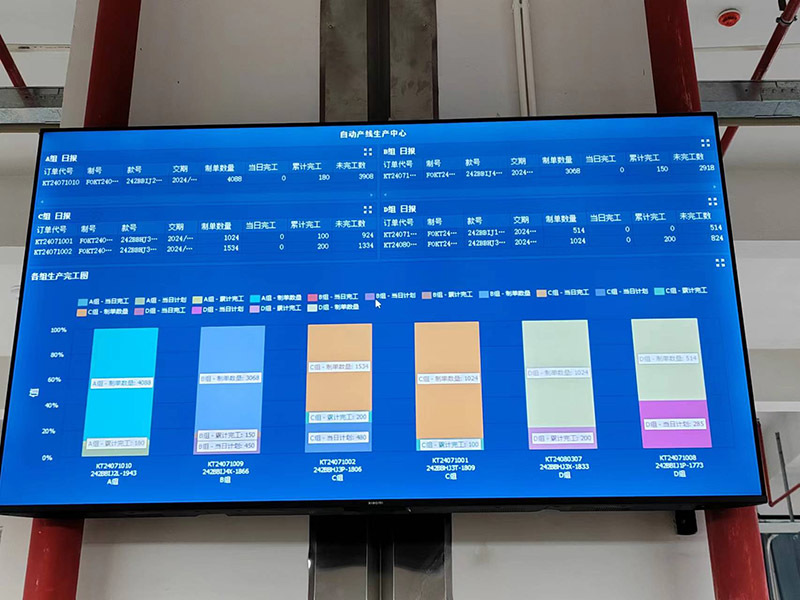

Efficient MES system

In order to cooperate with the automated assembly line, the workshop is equipped with MES system synchronously, which aims to strengthen the management and control of the production site, optimize the management of the entire production process from the order to the completion of the product through information transmission, and respond to real-time events in the production process in a timely manner. Provide plan execution, tracking and the current status of all resources (people, equipment, materials, customer needs, etc.). Through this system, the workshop can better implement lean production, greatly reduce non-value-added activities, better help production management guide production operations, improve timely delivery capabilities, material flow performance and production returns.

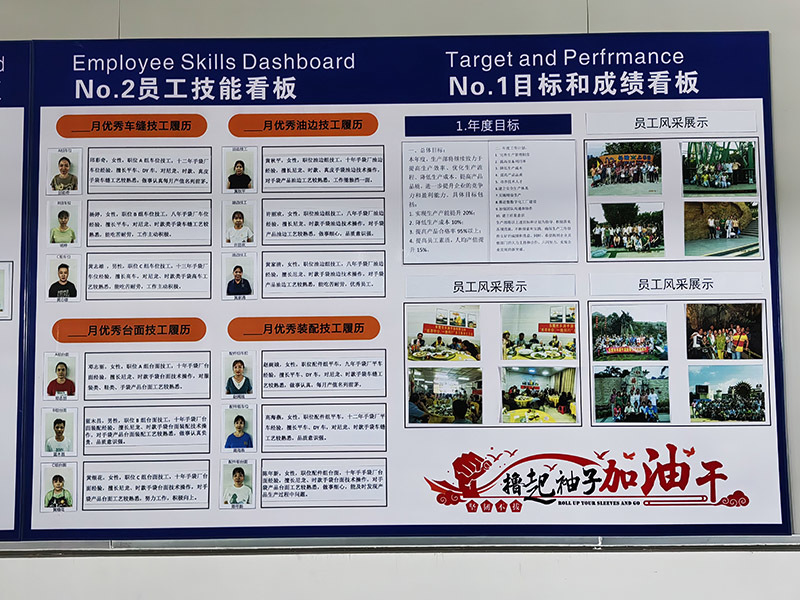

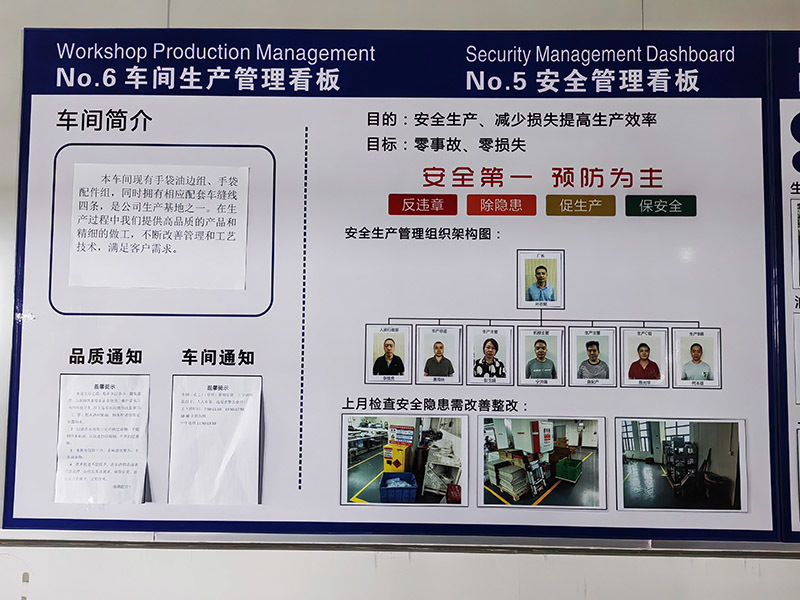

Unique production management model

The production team implements a piece-by-piece system to encourage employees to work more and earn more. At the same time, a series of awards such as standard award, over-production award, excellent employee award and full-time award are attached to reward efficient employees. At the beginning of each month, the heads of the three most efficient employees last month are posted on the bulletin board to stimulate employees to learn from role models and promote a virtuous circle. In addition to the basic salary, in order to strive for higher income, each management by leading their team to rush output value, control costs, so as to improve their team's surplus to obtain production commission. This approach has greatly stimulated the potential of each management and greatly reduced the occurrence of management inaction.

Strict quality management system

The company has a complete quality management system, the quality team for incoming inspection, semi-finished products inspection, finished product quality inspection, the implementation of a full range of quality control. The quality department requires timely discovery, timely tracking until the problem is solved. Its existence greatly reduces the rework rate and non-performing rate of production, largely reduces the occurrence of major quality accidents, and plays an escort role for smooth production.